charpy impact test results for copper|charpy impact test sample dimensions : distributor The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and . WEBIMVU Next. IMVU, the #1 interactive, avatar-based social platform that empowers an emotional chat and self-expression experience with millions of users around the world.

{plog:ftitle_list}

The Age of the Gods Book of Oracle online slot is a great addition to this Playtech series. It’s got an RTP which goes up to 96.48%, high volatility, and 10 paylines. Spin with expanding symbols and unlock the free spins round for games with multiple expanding symbols. Trigger the jackpot game with any spin to get . Ver mais

LCD Melt Flow Indexer factories

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . Charpy impact test is the most common technique for evaluating the impact toughness of materials under high strain rates (~10 3 s −1) 1. It has been reported that the impact toughness are.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and . The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

Melt Flow Indexer factories

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch .Understanding Charpy Impact Test results is essential for evaluating a material’s performance under impact loads and ensuring that it meets industry-specific standards—a critical aspect of material testing and design .

Charpy impact test is the most common technique for evaluating the impact toughness of materials under high strain rates ( ε ~10 3 s −1 ) 1 . It has been reported that the impact toughness are .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.EXPERIMENTAL ANALYSIS OF IMPACT STRENGTH AND COMPARISON OF IMPACT .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absorbed by the specimen during fracture. . When reporting the results of a Charpy test, the .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2. The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, . Charpy impact energy results for normal concrete [40], UHPC [38 ,43445152], and other advanced cementitious composites [53,54]. The results of these studies are too few and varied to re-E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials Figure 1. Schematic of Charpy Impact Testing and Izod and Charpy V-notch specimens Figure 2 Charpy V-notch specimen used in this laboratory showing dimensions Figure 3. Schematic of plot of impact energy versus temperature showing sigmoidal curveSplett JD, McCowan CN, Iyer H and Wang C Computing Uncertainty for Charpy Impact Machine Test Results NIST-SP 960-18 (2008) Siewert TA Evaluation Specimens for Izod Impact Machines (SRM 2115): Report of Analysis NIST SP 260-164 (2007) McCowan CN and Splett JD Analysis of Charpy Impact Verification Data: 1993-2003 Journal of ASTM International .

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .By doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the .For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.

Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to . While the results obtained from a CIT are not necessarily quantitative by nature, it is a . Two 1 cm diameter copper coils were mounted on a plate 70 mm apart, with their midpoint located at the impact location .The notch must be of specific dimensions and geometry to enable consistent results. Testing can be performed at both ambient and reduced temperatures, sometimes as low as -425F (254°C). Charpy Test Standards: Charpy impact testing is typically carried out following standards like ASTM E23, ASTM A370, or ISO 148. Although the test is more .

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. The use of materials that do not meet the requirements can have fatal consequences. When coldness and strong force Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

The purpose of this recommended practice guide is to demonstrate how to determine the uncertainty associated with mean absorbed energy of specimens tested on a Charpy impact machine. We assume that the Charpy machine has successfully met the requirements for both direct and indirect verification as described in the ASTM E 23, Standard .Standard testing procedure using the Charpy V-Notch (CVN) impact tests exists, i.e. the American Society of Testing Materials (ASTM) testing procedure E-23 [4], The results are plotted as CVN impact energy versus temperature as shown in Figure 1(a). In the plot, three regions can be identified as the lower shelf, the transition and the upper .

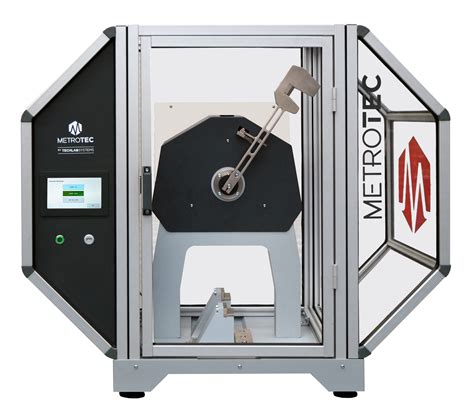

charpy impact tester

This paper investigates using the Charpy impact test as a certification test for a production batch. First, the best conditions for surface finishing and then the Charpy impact test results from one reference batch (defect-free) and one defective batch were compared. Hereinbelow are the main conclusions.This document provides information about conducting a Charpy impact test experiment to investigate how the energy absorbed during deformation and fracture of metals varies with temperature. The objectives are to determine the impact energy absorbed and percent shear of metal specimens tested at different temperatures. The experiment involves preparing and . Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

charpy impact test sample dimensions

charpy impact test sample

WEBLoterias | CAIXA

charpy impact test results for copper|charpy impact test sample dimensions